Content Supply Chain Management (Part 2)

The content challenge, or: How to tame complexity?

Always faster, always more. An irreversible trend.

Ever faster development cycles, more and more formats and distribution channels continue to determine the daily work in marketing, creative agencies and publishing houses as well as in many other team organizations. And while phrases such as “digital transformation” and “efficient collaboration” were the top buzzwords yesterday, today it’s “Artificial Intelligence”. AI creates images, writes stories in any language, summarizes texts, lets voices speak at will and even entire videos are possible. All thanks to the right prompt.

Regardless of ethical issues or the data basis on which AI was trained, it appears to be radically transforming many areas of work and automating manual tasks. Of course, the question of process control also remains and is unlikely to become less complex. And, let’s not kid ourselves, AI can create content in a matter of seconds. So if the growth in data “before” AI had not already been enormous, it is now getting another incredible boost.

The digital universe is not unlike the physical universe in that they are both vast. In 2013, it was estimated to contain around the same number of digital bits as there are stars in the universe. The source of this figure was an EMC study conducted with the IDC and published in May 2014 called “The Digital Universe”. And it is growing fast with all the data we generate and copy.

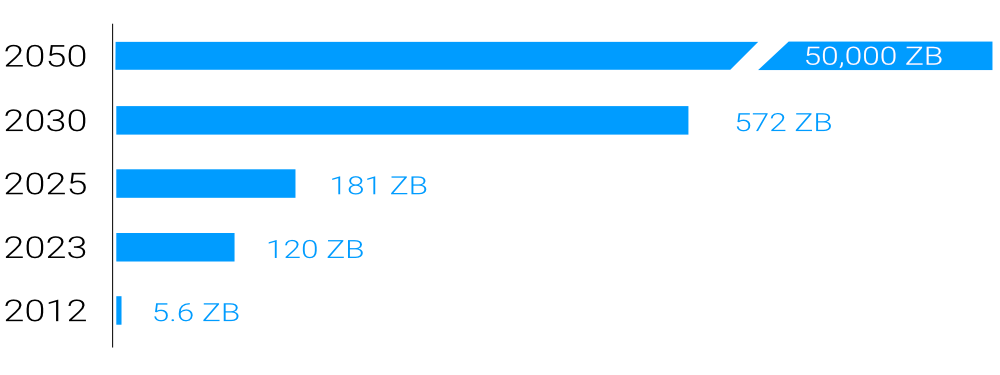

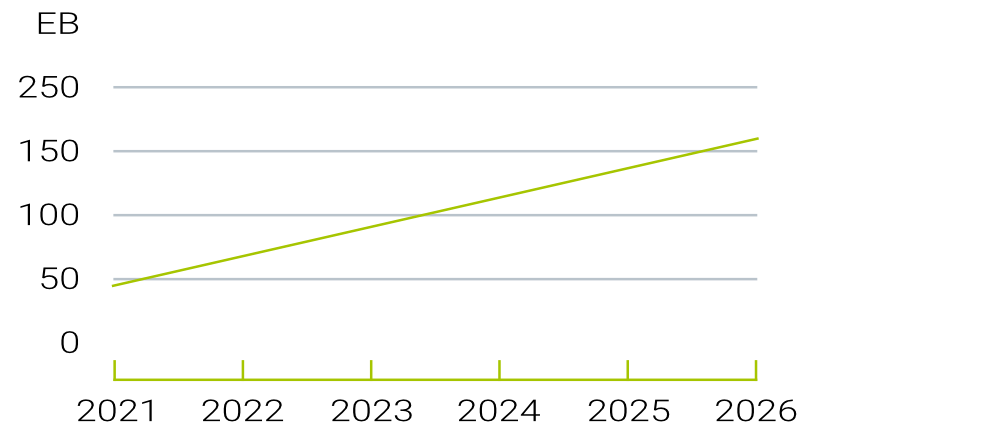

According to IDC and Huawai, the overall amount of data generated is expected to reach 572 zettabytes by 2030. And while the share of enterprise content is 47 exabytes today, it will reach 155 exabytes by 2026. And this growth will continue and accelerate in the years to come.

Global amount of data

Growth by 2012-2050 (expected)

1 Zettabyte (ZB) = 1,000,000,000,000,000,000,000 Bytes

Enterprise content

Growth by 2012-2026 (expected)

1 EB (Exabyte) = 1,018 Bytes; 1,000 EB = 1 ZB

How do we deal with this deluge of data?

Using manual processes and outdated tools such as e-mail and file servers, companies will lose an incredible amount of time and money in managing their content. From the initial idea, through implementation, review, versioning, and manual delivery in various formats, it can take days and weeks. Companies that do not have a future-oriented content management strategy only end up burning money and falling behind the competition.

Content Management is evolving into something of a value chain within the company. The more efficient this process can be made to be, the more time and costs can be saved along the way. These untapped resources may then be devoted to create more content or shorten time to market cycles.

The factors that figure most prominently in the content management value chain are:

- Efficient ways of creating, managing and providing any type of content

- Ability to reuse content at any time

- Convert formats to fit for any workflow, channel or touchpoint

- Integrate external and internal sources, new technolgies and service providers smoothly

- Quick and easy configuration of teams

Chart a new course to success

So what can companies and organizations do to tackle this problem and successfully reorganize themselves? Thinking outside the box leads to the solution, as the manufacturing industry and retail supply chains basically have similar problems: a huge variety of materials and products, complex production and delivery processes, many internal and external stakeholders and, last but not least, various connected systems. These problems are successfully solved with “Supply Chain Management” (SCM). The notion of end-to-end control over workflows that incorporate automated processes has been tremendously successful.

SCM is shorthand for the planning and management of all supply and logistics tasks, from selecting suppliers to procuring, manufacturing, and delivering goods. It is the tool used to coordinate collaboration among all the players, suppliers, merchants, logistics service providers and customers. SCM integrates management within the confines of an enterprise and beyond its boundaries.

An inspiring strategy: Supply Chain Management (SCM)

The roots of supply chain management date back at least to the 1980s when an early precursor to SCM concepts called just-in-time (JIT) manufacturing and its cousin, the just-in-sequence (JIS) inventory strategy, emerged. The idea behind JIT was to closely coordinate manufacturers and suppliers’ processes, which required major adjustments to the value chain.

Processes had to be linked so suppliers could track the materials consumed by manufacturers. They had to be made more flexible yet also more stable with an eye to improving quality. Shipping processes and cargo carriers had to standardized, for example, with uniform container systems and truck swap bodies. The Japanese concept of Kanban, or the pull principle, was instrumental in making all this work.

The following factors drove and shaped the emergence of SCM:

- A big-picture view of the total cost of ownership, or TCO, which called for greater cost transparency throughout the supply chain.

- The transaction costs incurred during the transition of material goods, communication problems, conflicts between process participants, risk factors due to political changes or climate effects, and so on.

- The bullwhip effect, which is an overreaction to unexpected demand caused by lack of transparency regarding actual demand, misinformation, frequent changes in inventory levels at various points in the process chain, and the like.

- The effects of globalization such as procurement on an international scale, cheap and fast transportation and communication, and worldwide competition.

- More demanding customers who want goods to be available worldwide, regardless of store opening hours, and insist on better quality.

The automotive industry and the retail sector, especially, began exploring notions of customer-centric process chains. While retailers came up with the idea of efficient consumer response (ECR), the Toyota production system changed the auto industry. Called the Toyota Way, its core precepts are to eliminate waste throughout the process to achieve Kaizen, Japanese for improvement. This has come to be known as the continuous improvement process, or CIP for short.

And this CIP continues all the time. There have been some groundbreaking innovations in SCM in the recent past in particular. Many manual processes have been further streamlined with automations, for example with AGVs (Automated Guided Vehicles) and IoT (Internet of Things) solutions. “Digital Twins” are now used for the big picture; they simulate scenarios and facilitate planning or risk management.

Studies show clear results

The Supply Chain Management Institute (SMI) of the European Business School (EBS), the management consulting firm McKinsey & Company, and the Bundesvereinigung Logistik (BVL or German federal logistics association) joined forces to conduct a study called “My Chain Delivers”. It investigated to what extent optimum SCM contributes to a company’s business success. The rewards of such a holistic approach to optimization are

- Up to 40 percent lower supply chain costs

- Up to 20 percent higher service level

- Up to 30 percent less inventory

And the positive effects are not limited to the supply chain. Companies that persistently practice SCM have been able to boost their overall revenues.

Let’s get back to content management, which is also a challenging task considering the massive amounts of data and complex processes. It cannot be accomplished without a scalable platform that is highly automated and can map all these complex processes. And as with the manufacturing industry and retail supply chains, content management also requires a holistic, comprehensive view – that’s what we call:

CONTENT SUPPLY CHAIN MANAGEMENT

The rewards of a holistic approach to optimization by Supply Chain Management:

Up to 40% LOWER COSTS

Up to 30% HIGHER SERVICE LEVEL

Process optimization by Supply Chain Management:

- Synchronize Processes

- Standardize Processes

- Prevent Errors

- Improve Manufacturing Systems

- Train and Qualify Employees

Deepen your knowledge

Take a deeper dive into the topic and learn more about the course you need to take. In the following parts, you will learn how to master the increasing complexity of content management, what content supply chain management is, how you can stay ahead with it, and whether even you can benefit from it.

Start

Revolutionize your way of managing content!

Part 3

What is Content Supply Chain Management?

Part 4

How to stay ahead with content operations?

Part 5

Who can benefit from a content supply chain?

Ready for take-off?

Bring your content management to the next level with vjoon.

Our experts will be happy to discuss your challenges and give you a personal demo.